|

Drill bits,Saw blades,Lawn mowers,Angle grinders|Garden Tools,Power Tools,Cutting Tools Supplier!

|

|

Main Technical Conditions Of Twist

Drill

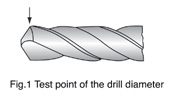

1). DimensionsDrill diameterThe values

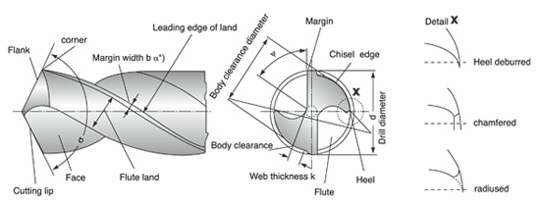

indicated in the relevant dimensional standards

apply in respect of the diameter of Twist

Drills.

Test point: On the lands at the

corners,(see Fig.l)

Testing equipment: micrometer

Tapering of diameter:The

diameter of twist drills usually reduces from

the drill tip towards the shank in the area of

the flutes.

Test values:The taper on

diameter amounts to 0.02 to 0.08mm over a length

of 100mm.

Test point: At the outside diameter

on the land.

Testing equipment: micrometer

and indicating measuring instruments.

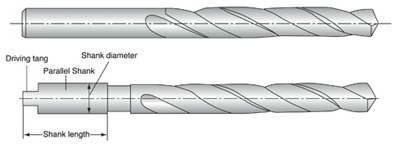

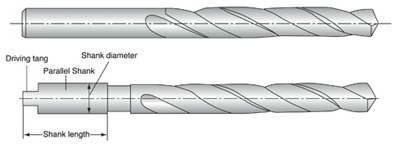

Parallel shank :Tolerance

for shank diameter f11,Tolerance for roundness

and parallelism 0.02mm for the shank length.

Concentricity tolorance(Tr.) The concentricity tolerance(Tr.) of

the Twist Drill is calculated from the equation.

Tr=O.03+O.O11/d

In

which I is the total length and d the diameter

of the drill (all dimensions in mm)

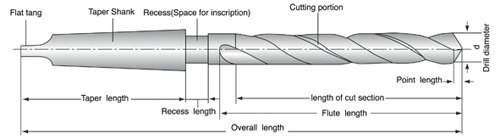

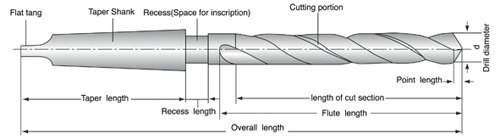

Length:The tolerance of

length for the total length corresponds for the

degree of accuracy very coarse according to DIN

7168 part 1.The flute lengths given in the

relevant dimensional stands are minimum

dimensions.

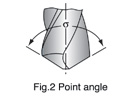

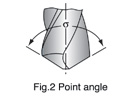

Point angle:Test

value:¦Ò=118¡ã;¦Ò135¡ã

Test point: At the cutting

edges(See Fig.2)

Testing equipment: Universal

bevel protractor indicating measuring

instruments.

2). Materials and

hardnessMaterials: M2; M35i M42;

F4341; 93410r4341;

Hardness:HSS HRC63-66

HSSCO HRC64-68

Test point: On outside

diameter on the land or adjacent relieved

land.

Test equipment: Hardness Tester.

3).

Making:Twist drills with

diameter 3mm and upwards shall be marked

with:

Diameter

Material:(HSS;HSSCO;)

Name or mark of

manufacturer.

Additional and/or differing

marking by agreement.

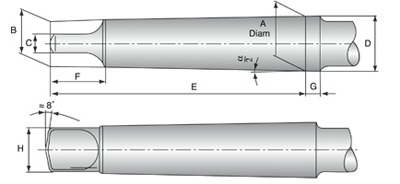

4). Twist Drill

with parallel shank

5). Twist Drill

with taper shank

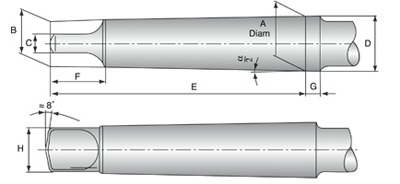

6). General

dimensions of morse taper

shanks

| Morse Taper Shank

A mmB mmC(h13)

mmD mmE mmF(max.) mm

G mmH(max.)

mm |

¦Á/2 |

| No.1 12.06595.2

12.26213.53.58.7 |

1¡ã25¡¯43 |

| NO.217.780146.3 18.07516513.5 |

1¡ã25¡¯50 |

| NO.323.82519.17.924.19420518.5 |

1¡ã26¡¯16 |

| NO.431.26725.211,931.6117.5246.524.5 |

1¡ã29¡¯15 |

| NO.544.39936.515.9 44.7149.5296.535.7 |

1¡ã30¡¯26 |

| NO.663.34852.41963.821040851 |

1¡ã29¡¯36 |

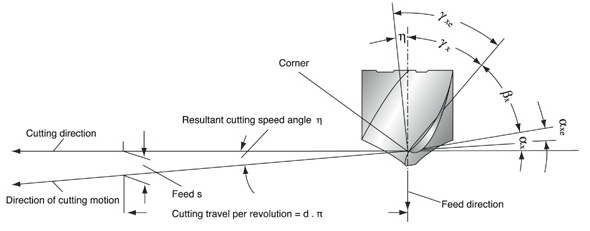

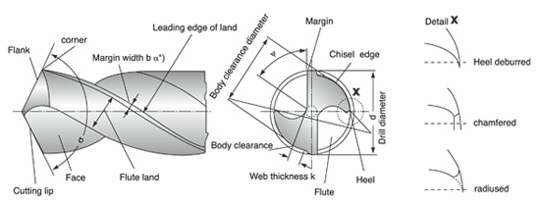

7). Cutting portion  ¦Ò= Point angle (sigma) ¦Ò= Point angle (sigma)

¦× = Chisel edge

angle(psi)

*)In the context of cutting

technology, land width b is the body clearance

land width which is to be by bfan see

DIN 6581.

8).

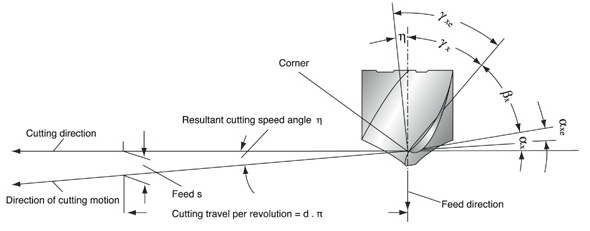

Angle at the cutting edges The corner has been adopted as the

observed edge point

¦Áx=Side clearance angle

(alpha)

¦Áxe=Effective side

clearance angle

¦Âx=Side wedge

angle(beta)

¦Ãx=Front rake

angle(gamma)

¦Ãxe=Working front

rake angle

¦Ç=Resultant cutting speed

angle(eta)Clearance angle ¦Á,wedge angle ¦Â and rake

angle¦Ãare measured in the tool orthogonal plane.

For details, see DIN 6581, definitions of

metal-cutting technology; geometry at the tool

edge.

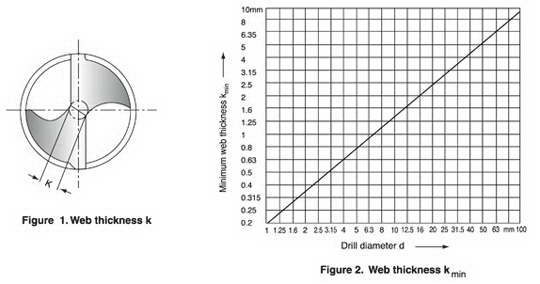

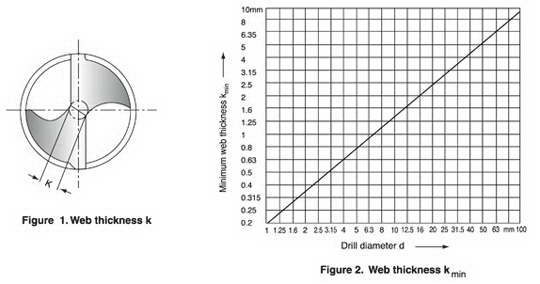

9). Web thickness

KTest values:The web

thickness according to Fig.1 shall not be less

than the minimum value kmin indicated

in Fig.2.Test point: At

the point of the drill.

Testing

equipment:Slide gauge with measuring

points.

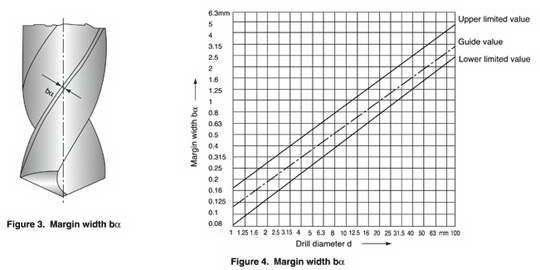

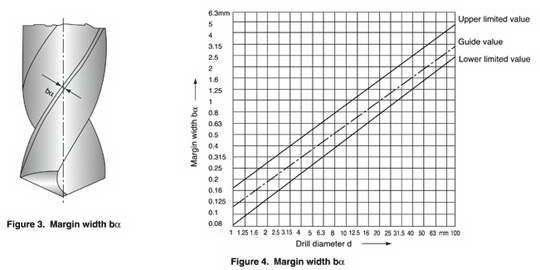

10). Margin width

b¦Á Test values: The land width

as in Fig.3 shall lie within the limitting

values indicated in Fig.4 Test

point: 5mm behind the corner

Testing equipment: Slide

gauge

11). Angle on

twist drills (1)Side rake angle ¦Ãf (Helix angle) Recommended

test value: Recommended ranges

depending on the tool types N,H and W according

to DIN 1836 and the diameter of the drill

included in Fig.5

Test point: At the corner, see Fig.6

Testing equipment: According to VDI Guideline 3331 Part1

,Section Margin widthb¦Á

Note:The side rake angle

¦Ãfis measured in place of the

orthonagonal rake angle ¦Ão found in

the wedge measuring plane(see DIN 6581),as this

changes along the cutting edge(becoming smaller

towards the point of the drill)

(2) Point angle ¦Ò

test value: Usual

executin for tool types N and H:¦Ò =118¡ã,for tool

type W:¦Ò =130¡ã

Test point: At the cutting, see Fig.7.

Testing

equipment: According to VDI Guideline

3331 Part 1, Section Margin width

b¦Á

12). Resharpening

Twist drills (1) Drills are worn off

irregularly.It should be sharpened prior to

developing into excessive wear.(2)

Resharpening

¢ÙGrind the correct

point angle to suit your application.(figure 8)

¢ÚCheck that both cutting lips have the same

angle. On a 130¡ã point,each lip should be 65¡ã

toward the axis.The point must be on center,

i.e.,the chisel edge must produce cutting lips

of equal length.(figure 8)

¢ÛGrind Primary

relief and Secondary clearance,(figure

9)

¢ÜGrind web thinning.(figure 10)

13). Web

Thinning (1) Without thinning

Suitable for drill of

general purpose.Thanks to thin web thickness,

web thinning is not need.

This without web

thinning type is applied to design of drills for

mild steel, alloy steels, cast iron, stainless

steel, titanium, inconel, etc. and conventional

cutting conditons.

(2) Type C thinning

(DIN 1412 FORM C,SPLIT POINT)

Because Split

point enables good centering

when drilling

and breaks the chips,chip removals is

easy.

Suitable for drill design in high

hardened tough materials,i.e, heat treated

steel, titanium alloy,

stainless steel, incoroy inconel, nimonic,

etc.

(3) Type R thinning (HEI.ICAL

THINNING)

Helical thinning ensure to frequent

chip breaking and removal. The different

direction force of cutting edges and helical

thinning parts enables that chips curl, break

and remove through the flutes. In addition

helical thinning makes the chip room up to

center, remove the chisel and enables good

centering.(4)Type A thinning (DIN1412 FORM A)

A type

thinnings makes thin chisel, good chip removal

and favorable centering.

This type is the

easiest type to grind the thinning. In narrow

web and wide fluted drills,keeping of the

rigidity and smooth chip removal are

possible.(5) Type B thinning (DIN1412 FORM B)

In

case of work materials with low cutting

resistance and good chip removal,ie,cast

iron,aluminium, plastic etc, B type thinning is

suitable.

Especially when drills for high

hardended steels are designed, this type is

applied to decrease rake angle and avoid

chipping of cutting

lips. |

¦Ò= Point angle (sigma)

¦Ò= Point angle (sigma)